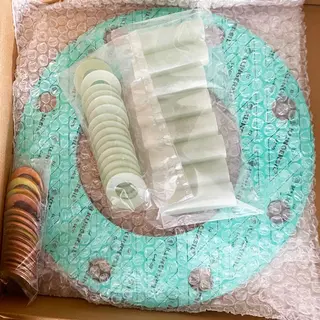

Gaskets serve as crucial sealing elements for various types of equipment, including pumps, pipe valves, pressure tanks, reaction tower kettles, and more. They are positioned between two flanges to enhance the seal and prevent leakage at the joint. TOPPER primarily offers two types of gaskets: metal gaskets and insulating gaskets (graphite gaskets, PTFE gaskets). The metal gaskets consist of spiral wound gaskets and metal ring gaskets, which are predominantly utilized in the petroleum, petrochemical, and food industries. Meanwhile, flange isolation kits are specifically designed for use in cathodic protection systems within pipelines.

The Flexible Graphite Gaskets Plant in China specializes in producing high-quality gaskets tailored to meet customer requirements. These gaskets are designed with a carbon content of 98%, ensuring excellent thermal and chemical resistance. They have a density of 1.0–1.1 g/cm³ and can withstand pressures up to 40 bar. The gaskets are available in a wide range of dimensions, from 1/2 to 60 inches, and can be customized to fit specific customer needs.

The Corrugated Graphite Gasket Manufacturer produces high-quality gaskets with a carbon or stainless steel core, covered with flexible graphite. These gaskets are available in sizes ranging from 1/2 to 60 inches and are designed for use in Class 150 and 300 LB applications. With a thickness of 2.38 mm, they offer excellent sealing performance and flexibility, making them suitable for a wide range of industrial applications where durability and reliability are essential.

ASME Standards: ASME B16.20, ASME B16.21, ASME B16.5, ASME B16.47

ANSI Standards: ANSI B16.20, ANSI B16.5, ANSI B16.47, ANSI B16.21

API Standards: API 6A, API 605

Other Common Standards: NORSOK, NORSOK L-005, MSS SP-44, BS 1560, DIN, JIS, JPI, HG, SH

Carbon Steel

SS 304, SS 304L, SS 316, SS 316L, SS 347, SS 347L, SS 321

Hastelloy B3, Hastelloy C276, Incoloy 800, Incoloy 825, Alloy 20, Monel 400, Inconel 600, Inconel 625, Inconel X750

Titanium, Nickel200, G7, G10, G11, Phenolic, CR+Phenolic, RPTFE, Nitrile, EPDM, CR, Viton, Teflon, Mylar, Nomex, Rubber, Neoprene, Asbestos, Non Asbestos, NBR, PTFE, E-PTFE

Nominal Diameter: DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN90, DN100, DN125, DN150, DN200, DN250, DN300, DN350, DN400, DN450, DN500, DN550, DN600, DN650, DN700, DN750, DN800, DN850, DN900, DN950, DN1000, DN1050, DN1100, DN1150, DN1200

Outside Diameter: OD21.3 mm, OD26.7 mm, OD33.4 mm, OD42.2 mm, OD48.3 mm, OD60.3 mm, OD73 mm, OD88.9 mm, OD101.6 mm, OD114.3 mm, OD141.3 mm, OD168.3 mm, OD219.1 mm, OD273.1 mm, OD323.9 mm, OD355.6 mm, OD406.4 mm, OD457.2 mm, OD508 mm, OD559 mm, OD610 mm, OD660 mm, OD711 mm, OD762 mm, OD813 mm, OD864 mm, OD914 mm, OD965 mm, OD1016 mm, OD1067 mm, OD1118 mm, OD1168 mm, OD1219 mm

NPS: 1/2 Inch, 0.5 Inch, 3/4 Inch, 0.75 Inch, 1 Inch, 1-1/4 Inch, 1.25 Inch, 1-1/2 Inch, 1.5 Inch, 2 Inch, 2-1/2 Inch, 2.5 Inch, 3 Inch, 3-1/2 Inch, 3.5 Inch, 4 Inch, 5 Inch, 6 Inch, 8 Inch, 10 Inch, 12 Inch, 14 Inch, 16 Inch, 18 Inch, 20 Inch, 22 Inch, 24 Inch, 26 Inch, 28 Inch, 30 Inch, 32 Inch, 34 Inch, 36 Inch, 38 Inch, 40 Inch, 42 Inch, 44 Inch, 46 Inch, 48 Inch

R Size: R11, R12, R13, R14, R15, R16, R17, R18, R19, R20, R21, R22, R23, R24, R25, R26, R27, R28, R29, R31, R32, R33, R34, R35, R36, R37, R38, R39, R40, R41, R42, R43, R44, R45, R46, R47, R48, R49, R50, R51, R52, R53, R54, R55, R56, R57, R58, R59, R60, R61, R62, R63, R64, R65, R66, R67, R68, R69, R70, R71, R72, R73, R74, R75, R76, R77, R78, R79, R80, R81, R82, R84, R85, R86, R87, R88, R89, R90, R91, R93, R94, R95, R96, R97, R98, R100, R101, R102, R103, R104, R105

RX Size: RX20, RX23, RX24, RX26, RX27, RX31, RX37, RX39, RX41, RX44, RX45, RX46, RX49, RX50, RX53, RX54, RX57, RX63, RX65, RX69, RX73, RX82, RX84, RX85, RX86, RX87, RX88, RX89, RX90, RX91, RX99, RX201, RX205, RX210, RX215

BX Size: BX150, BX151, BX152, BX153, BX154, BX155, BX156, BX157, BX158, BX159, BX160, BX161, BX162, BX163, BX164, BX165, BX166, BX167, BX168, BX169, BX170, BX171, BX172, BX303

IX Size: IX15, IX20, IX25, IX40, IX50, IX65, IX80, IX100, IX125, IX150, IX200, IX250, IX300, IX350, IX400, IX450, IX500, IX550, IX600, IX650, IX700, IX750, IX800, IX850, IX900, IX950, IX1000, IX1050, IX1100, IX1150, IX1200

FG Flexible Graphite, Flexible Graphite, Asbestos, Non-Asbestos, PTFE, MICA, CER, Ceramic, E-PTFE, NAF, ASB

1.5mm, 3mm, 3.2mm, 4.5mm, Customized

Oil, Zinc Coating, PTFE Coating

Blue, Yellow, Orange, Black

Class 150 LB, 300 LB, 400 LB, 600 LB, 900 LB, 1500 LB, 2500 LB

PN20, PN50, PN64, PN100, PN150, PN250, PN420

Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500

150#, 300#, 400#, 600#, 900#, 1500#, 2500#

5000 PSI, 10000 PSI, 15000 PSI, 20000 PSI